According to the most recent Worldwide CAD Trends report, which surveys CAD users such as designers, engineers, and professionals, including managers and senior executives, many enterprises rely on CAE technologies to enhance design productivity and shorten time-to-market.

In fact, seventy-nine percent of manufacturers surveyed are investing in CAE, including seven out of every ten small and medium enterprises (SMEs). This means that more and more of your competition is looking for ways to improve their processes and make themselves more competitive.

While the database-driven characteristics of modern CAE platforms, like EPLAN, offer a wealth of benefits, one of the most dynamic is the collaborative opportunities they afford. If you think of an organization as a living thing, then its data is the bloodstream that touches and supports every part of the organization.

Having access to this data creates more effective communication channels both across and within teams in an  organization, both of which were cited as challenges by 45% and 31% of respondents in EPLAN's 2017 State of Engineering Design Technology study (research report to be released shortly). Working at the same time instead of in the traditional “in sequence” method offers many new opportunities.

organization, both of which were cited as challenges by 45% and 31% of respondents in EPLAN's 2017 State of Engineering Design Technology study (research report to be released shortly). Working at the same time instead of in the traditional “in sequence” method offers many new opportunities.

Instead of passing designs “over the wall” and having each discipline work in isolation, engineers can now collaborate on the design in real time. This allows a much quicker design process, which in turn benefits other departments within the organization. For example, sales can provide quotes more quickly, and actual machine building can begin sooner.

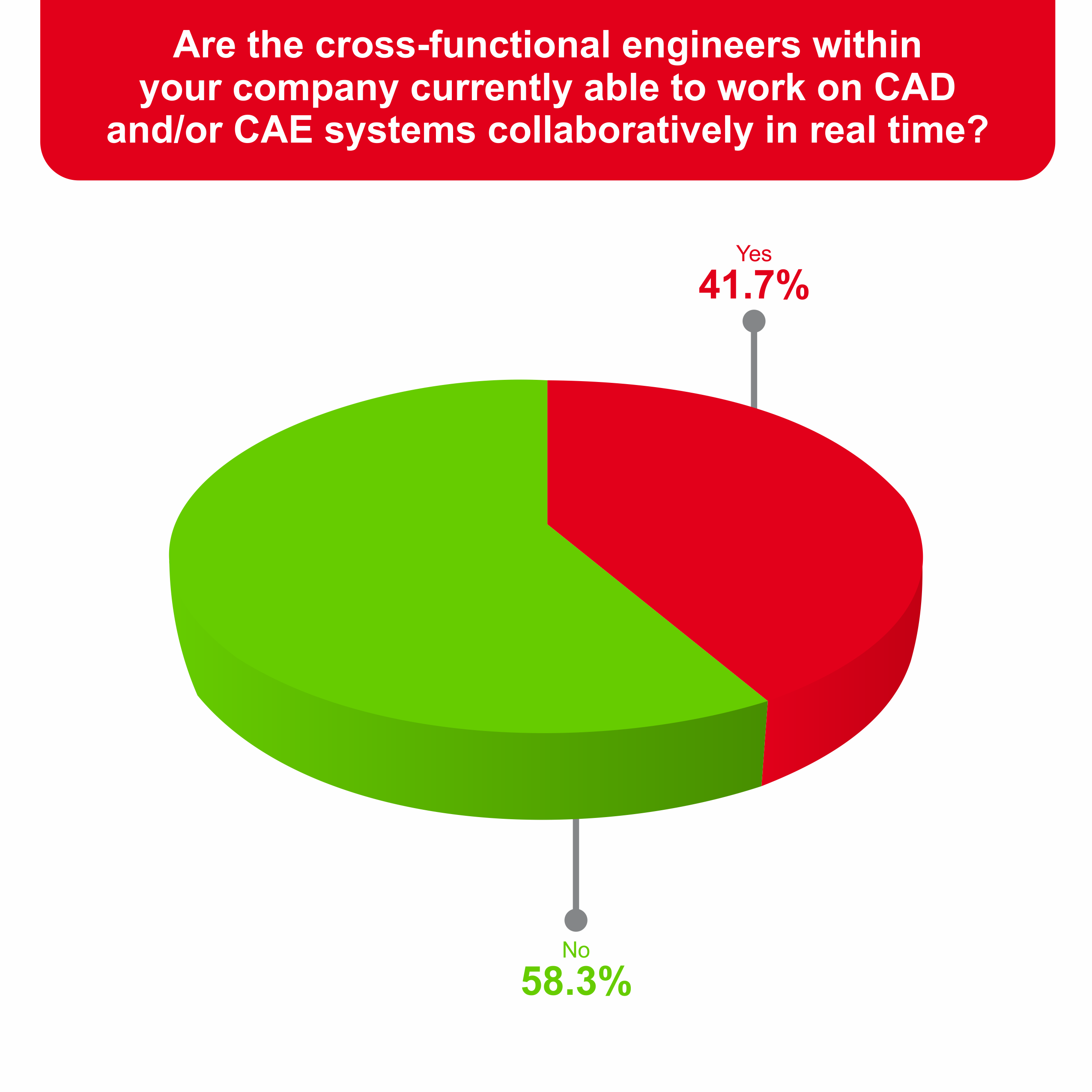

However, a concerning insight from the EPLAN 2017 State of Engineering Design Technology study shows that only 41.7% of engineering organizations are able to work on either CAD or CAE systems collaboratively in real time.

It is easy to see how much productivity opportunity is being missed - here at EPLAN, we hope to help.