Author

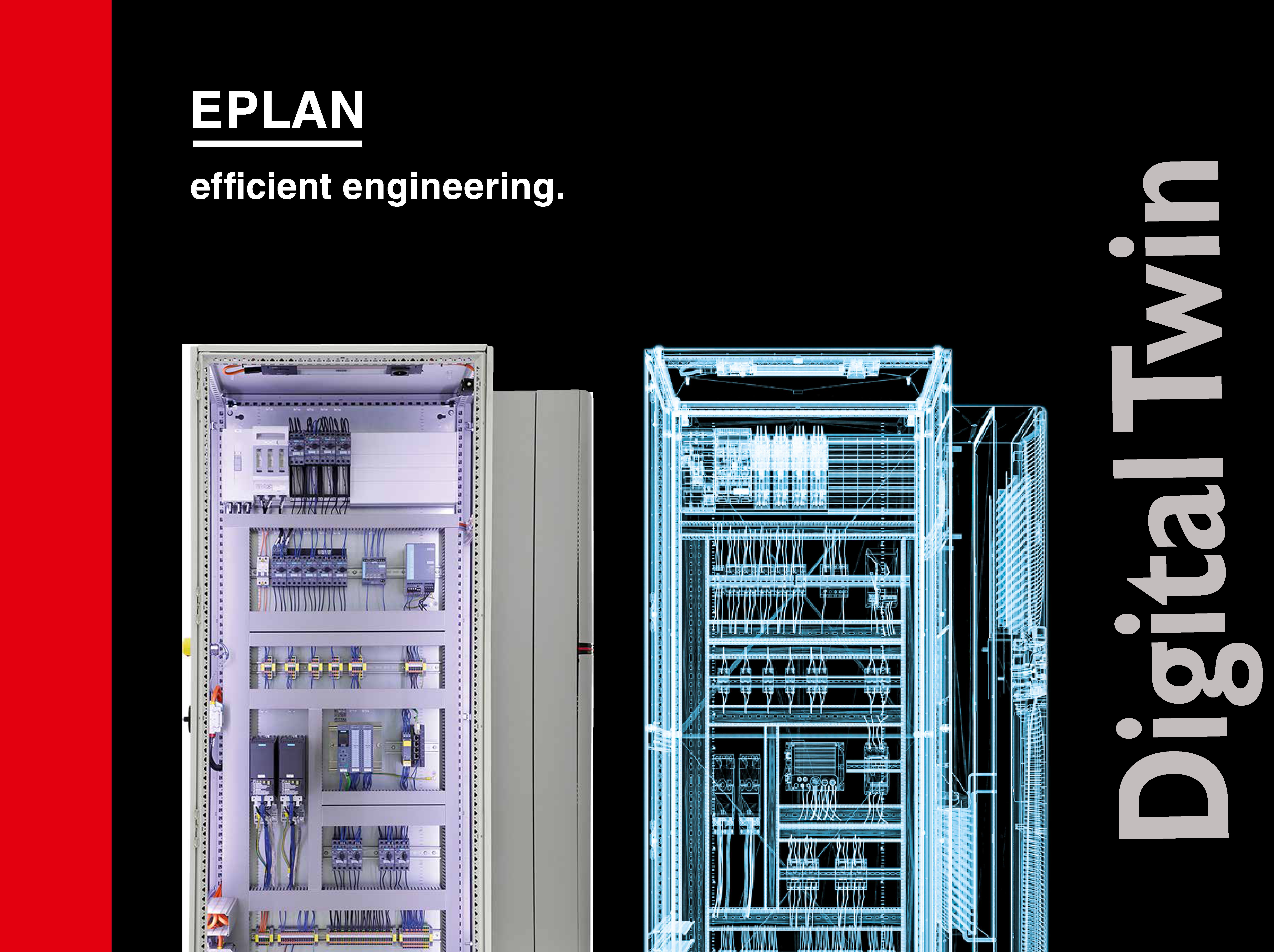

Digital Twin – The Virtual Replica of Your Designs

A recent Gartner survey has noted that the concept of the Digital Twin is now entering mainstream use.* A Digital Twin is an accurate virtual model of a process, product or service. The behavior of this model can almost always be analyzed more easily and at a lower cost than the behavior of its real-world analog. Not only can this allow designers to accurately mimic functionalities of the original component, but it offers the possibility of experimentation without any risks. In the real world, this would inevitably cause concerns if the component was altered.

A part of this digital twin includes a process which involves smart components, which are sensors used to gather data about real-time status, working conditions, or positions, and are integrated within the physical item or machine component. The components are then connected to a cloud-based system that receives and processes all the data the sensors monitor. This input is analyzed against business and other contextual data.

The use of the Digital Twin varies depending on the manufacturer’s business model. Sometimes, it can be used to develop the early design stages to inspect how a component or device will perform. Another important function is simulating the operation of a new machine/ or device before it is used in a live environment. These applications help reduce the cost, as well as the risk of errors associated with product development. Would you like a demo of the Digital Twin? Click here.

Comments