Author

What is EPLAN?

We develop one of the world’s leading computer-aided engineering (CAE) design software solutions for machine and panel builders with our bespoke electrical design software packages and consultancy services, which are tailored to assist you with simplifying challenging engineering processes.

"Efficient engineering" is our focus: we are the ideal partner to streamline challenging

engineering processes. No matter whether you are a small, medium or large company, we strive to enable our customers to apply their expertise more efficiently.

Are you a design engineer that spends a lot of costly time carrying out manual, repetitive tasks like wire numbering, producing terminal schedules and repeatedly redesigning common circuit blocks? Many of these tasks can be automated, saving money and freeing up time for engineers to concentrate on more creative work. Read on to discover how CAE differs to CAD and why it’s revolutionary...

What is the EPLAN Platform?

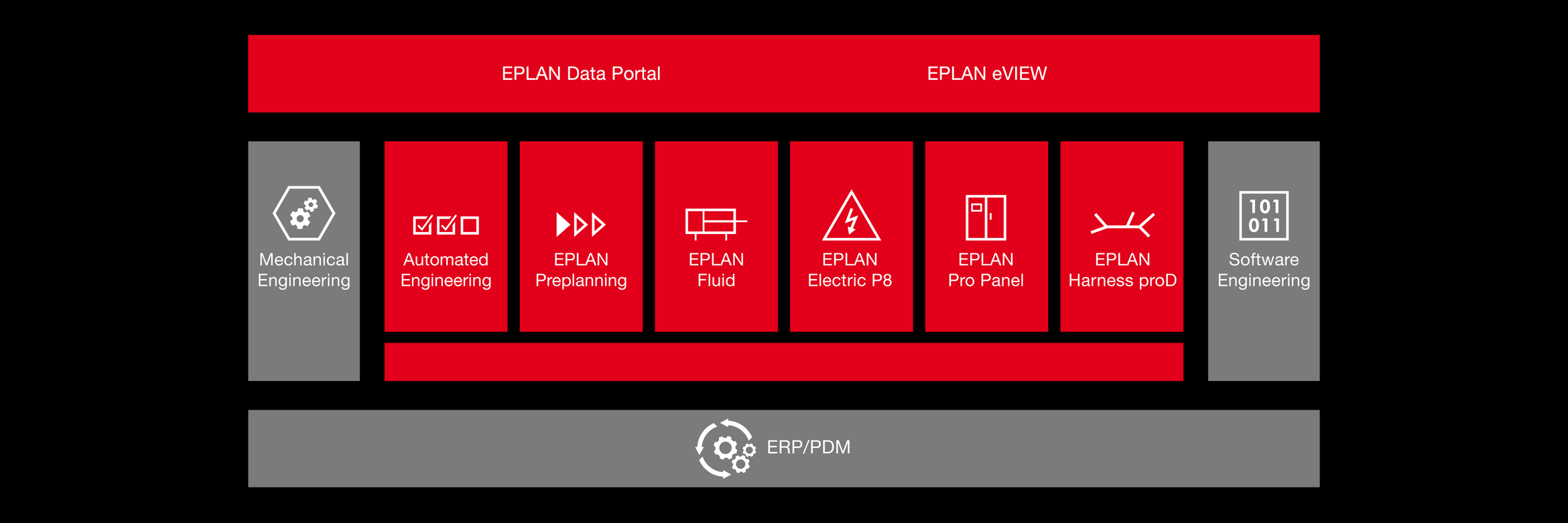

Up-to-date, digital data lays the foundation for efficient engineering. The EPLAN Platform connects all EPLAN software solutions to one another, and forms the basis for the expert systems that you use to create projects, thus creating transparency in your engineering processes. . This enables you to work on your engineering projects in an interdisciplinary manner and have the optimal solution for every type of application. Optimization potential in your engineering processes lies in introducing parallel engineering and having true insight in to what is happening at all stages in a project. The EPLAN Platform makes this optimization potential a reality by providing you with real-time information at all times.

Another benefit of the EPLAN Platform is that it connects to interfaces to enable bidirectional data exchange with ERP and PDM systems. This means that EPLAN project data can be transferred to mechatronic solutions and other software environments for seamless processing. By using electrical design software solutions in the EPLAN Platform, you can revolutionize your design process through the seamless integration of data across your entire project or business, saving you time, ensuring accuracy and thus solidifying your credibility.

The EPLAN Platform Graphic

The EPLAN Platform Graphic

CAD vs. CAE

CAD is an individual software package that offers an electronic version of a drawing desk. It usually offers no more than visual information to the following team in the process, which creates data breaks in a company’s processes. Information is copied manually from one team to another, resulting in errors.

On the other hand, CAE systems are individual software packages that combine, edit and insert data onto a common platform. Each change made is instantly updated in the other software packages, meaning real time changes and true multi-user interaction is achieved. Information is exported into a multitude of formats to allow clarity of meaning throughout the process and giving everyone involved in their process their own view that is correct and error-free.

So you’ve seen a couple of the benefits to using CAE rather than CAD, but is that it? No!

The mechanical world has moved on from CAD, and it’s time for the electrical design world to catch up and use the innovative tools available.

Mechanical doesn't, so why do you?

Firstly, the mechanical world has been utilizing re-usable data for quite some time. They rely on the data being stored correctly and diligently, allowing several engineers to work independently with the combined effort shown on the full model. By implementing standardization and having a library or pre-defined components that you can reuse in projects, you save a huge amount of time and no longer have to start from scratch every time you start a new project with manual creation. Think about the amount of time you could spend doing the design work you really enjoy rather than the manual, laborious data creation.

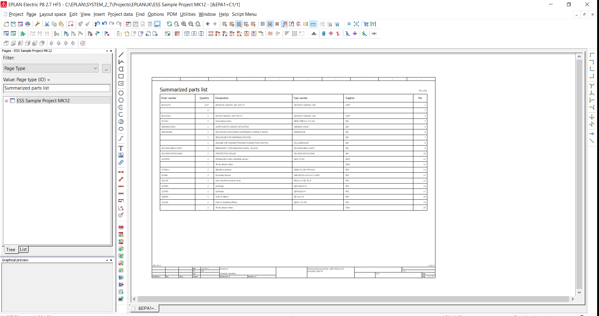

Secondly, electrical schematics were, and often continue to be, perceived as a simple 2D drawing - just some wires and symbols so the panel builder can work it out. An electrical schematic is actually a 2D drawing with data that can be utilized across the entire company to increase the company’s productivity. For example, you can easily produce a Bill of Materials (BOM) from the schematic drawing, which makes purchasing’s task much easier.

Automatically created BOM in EPLAN.

Lastly, an engineer can now “draw” a device in several ways using macro and variant technology, and select the most appropriate variant for the project at hand. Creating a library of macros and variants speeds up your electrical design time and ensures that any errors are eliminated. This re-usable data stored in a reliable manner gives the same benefits the mechanical engineers have appreciated.

It’s clear that CAE is beneficial and it’s time to come up to speed which mechanical, but what are the other benefits?

Change Processes - out with the old, in with the new

CAD drawings are difficult to update. For example, renaming pages or devices can takes several hours of laborious clicking and typing for even a minor change in design. However, with a CAE system, cross references, device tags, wire numbering and even page numbers are manipulated via the platform and capable of extensive, instant and error-free changes. Any change made is automatically updated in the system and everyone involved in the project is informed and kept up to date – making the change process seamless. CAE software also has a revision management system, which tracks and reports all changes made with minimal effort.

Just think about the amount of time that automatic change updates will save you.

Comprehensive Product Database

Data is the backbone of efficient design and any CAE system, but creating data can be laborious. Did you know that manufacturer-approved data is readily available in multiple platform formats? The EPLAN Data Portal hosts component data from well-known manufacturers around the world. You can simply download the data straight into your project and use it immediately. Simple transfer of the components’ data in the project reduces the engineering effort and increases the quality of the machine and plant documentation – a win-win situation!

EPLAN Data Portal component manufacturers.

And there’s more …

3D Design Benefits

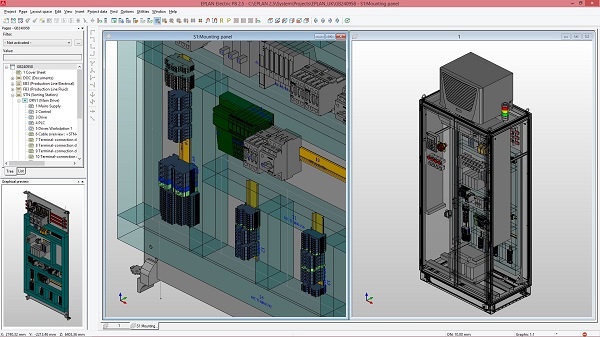

Within the EPLAN Platform, digital device data includes 3D models for placement in panel design. That sounds nice, but what are the benefits to designing in 3D- and the benefits to using EPLAN?

- Easily see if everything fits in the panel – avoid errors in the manufacturing phase and increase accuracy

- See where potential collisions may happen and avoid them

- Save space and purchase a smaller panel if you have lots of free space – saving costs!

- Generate wiring lists and data to ensure efficient wiring – Take a look at EPLAN Smart Wiring

- Generate drilling patterns for automated machining – increases safety, productivity and efficiency

- Create a digital twin – easier to work with, gives you a digital replica

- Quicker service and maintenance because everything is clearer in the design

- Accurate BOM and cable lengths – reduces scrap

- See where cooling is required in the cabinet because of hot components

EPLAN Pro Panel allows quick and easy design in 3D.

EPLAN Pro Panel allows quick and easy design in 3D.

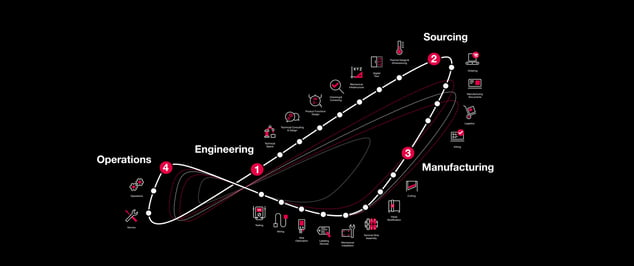

The Unique EPLAN and Rittal Value Chain

We believe in engineers, in their creativity and inspiration, so we do everything possible to help them make their ideas reality. We also push them to become even more innovative and creative, which is key to a successful future in the digital age of Industry 4.0.

Our sister company, Rittal, is the world’s leading systems provider for enclosures, power distribution, climate control, IT infrastructure and software & service. The Rittal Automation Systems (RAS) division allows companies to automate panel building with machines and devices that make enclosure assembly easier, faster and more accurate. You can create a 3D panel in EPLAN Pro Panel – a 3D software solution for designing control cabinets – and export the model straight to a RAS machine, like the Rittal Perforex, which will automate the drilling and cut outs in just a few clicks.

Using EPLAN software to design an enclosure gives a complete 3D panel design with all of the manufacturing data that the workshop requires. The data can be easily exported in the correct format to the workshop with just a few clicks. If your company has a drilling or cutting machine, the data can be automatically exported to the machine. This enables the workshop to automatically gain data that they can immediately start working with. This reduces error because the workshop aren’t having to second guess the 2D drawings as all the data provided is correct. In addition, it saves time because data is exported in just a few clicks and sent straight to the workshop – so if your workshop is far away, you no longer have to walk the data to it! This creates an efficient process through the extended business.

EPLAN and Rittal work together to create a unique solution from design through to manufacturing.

Would you like to know more about EPLAN?

Comments