Author

Achieving Quality Standards in 4 Steps

To engineer more efficiently, you have to set up an environment to work with EPLAN, which includes creating guidelines and standards in your systems, design methods, and processes. This enables you to structure your machines or installations in your own standard. You can accelerate the engineering process and respond to changing customer requirements more flexibly with the help of both advanced engineering and the creation of modules.

Choose a Design Method

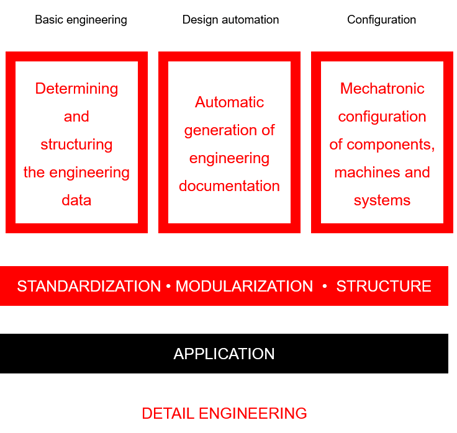

In order to choose a good structuring for your products and projects, the design method that you use is important. The design method must align with your company’s vision and strategy. Questions such as ‘What are we good at?’ and ‘Which markets do we want to operate in?’ help to determine whether you choose basic engineering, automation, configuration, or a combination of these design methods.

The design method you choose will determine the best way to complete the following steps.

Choose a Structure

There are many ways you can separate your products into reusable modules. Which structure influences your customers, products, and engineers the most? There are different factors that affect this. A better question is, ‘How do you and your engineers create a library of reusable modules?’

1. Agree the Structure and Definitions

Engineers from different disciplines (mechanical, pneumatic/hydraulic, electrical and software) should agree on:

- Definitions

What do we mean by a conveyor belt? Make sure engineers from different disciplines have the same definition for modules to ensure consistency in communication. - Functional modules

Which components does the machine or installation have? Where do we draw the line between them? For the best result we should choose multidisciplinary modules where possible, i.e. modules that contain a mechanical, electrical, and software component. - Norms and standards

Which standards can we use to structure our standardization? Think about IEC 81346 for structuring systems and documentation and IEC 62491 for labeling cables and clamps.

Engineers from different disciplines will think about this differently. The challenge is to establish a common structure and definitions that engineers from different disciplines agree on. By doing this in advance, we prevent miscommunication and problems that would have to be solved later in the process.

Tip: Have an independent standardization manager who is above both parties to accelerate these conversations and improve the output.

![]() Having a clear structure makes the entire process simpler and easier for all involved.

Having a clear structure makes the entire process simpler and easier for all involved.

2. Arrange the Library

The next step is to store the chosen definitions and structure in your systems. Every department should store its own part of the module in its own system. The electrical engineers can do this in EPLAN with the help of macros.

Tip: Make the engineers who agreed the structure and definitions responsible for the arrangement and management of the library as well.

3. Choose how to Present the Information

Dividing the functional modules between the different disciplines calls for another method of creating and reproducing information. In this phase, the multidisciplinary team agrees on the drawing method. The information that will be stored in these schematics is important. The more comprehensive the information is, the more cluttered the drawing is. For a panel builder, such a drawing becomes unreadable very quickly.

What is the solution? Generate lists with all of the relevant information for each discipline. In this phase, it is also important that we include other, non-engineering departments in the process, such as purchasing, sales, panel builders, and service technicians. What information do they need to complete their work? What is the most effective way of presenting this information?

4. Manage Change

The bigger the efficiency improvements, the bigger the change. This can affect all parts of your engineering:

- Structure - a division of products into modules and/or technical solutions by function.

- Process flow - because engineering is largely advancing, engineering disciplines can design in parallel with each other.

- Design Methods - the way of presenting can also change. Voltage-oriented schematics are replacing functional schematics. Single-line schematics are replacing generated lists. The panel builder, software engineer, and technician receive lists that have been specifically generated with the information that is relevant to them.

A change like this requires attention. Engineers who have been working in a certain way for years now have to start thinking and working differently. Managing change is often forgotten but helps to ensure a successful standardization.

Tip: Appoint a change manager for this process.

Get started!

Have you completed the four steps? You can now apply the new structure and method to your project. By using a module library, your team can shorten the lead-time of a project and improve your product's quality.

Configure-to-order (CTO), Engineer-to-order (ETO), or both?

Can you completely configure your project via CTO? That depends on your projects and your customer's requirements. For example, the solutions are very specific to the customer in the processing industry. Can you standardize everything? Firstly, configure your solution as much as you can using CTO to get as close to the customer requirements as possible, then complete the project through the specific engineering needed (ETO). With this approach, you save a considerable amount of time. Interested in our infographic? Learn how to keep constant quality data with our free guide below!

Comments